The landscape of food processing has undergone a remarkable transformation over the past decade, driven by an insatiable demand for products that are not only safe and convenient but also nutritionally dense and sensorially superior. This evolution marks a significant departure from traditional methods, which often prioritized shelf stability and mass production at the expense of nutritional integrity and quality. Today, the industry stands at the intersection of technology and wellness, where innovation is relentlessly focused on a dual objective: preserving the inherent goodness of raw ingredients while simultaneously elevating the overall eating experience. This paradigm shift is not merely a trend but a fundamental reimagining of how we approach food from farm to fork.

Central to this modern revolution are novel thermal and non-thermal processing technologies that challenge the dominance of conventional heat-based methods like pasteurization and sterilization. While effective for microbial safety, these traditional techniques are notoriously harsh, often leading to significant degradation of heat-sensitive vitamins, antioxidants, and other bioactive compounds. In response, techniques such as High-Pressure Processing (HPP) have surged in prominence. HPP subjects sealed food products to extremely high levels of hydrostatic pressure, effectively inactivating pathogens and spoilage microorganisms without the application of heat. The result is a product that retains a fresh-like character, vibrant color, and most importantly, a nutritional profile that closely mirrors its unprocessed state, extending shelf life without compromising on health benefits.

Another frontier of innovation is found in the realm of advanced drying technologies. Moving beyond simple hot-air drying, which can cause shrinkage and nutrient loss, methods like freeze-drying (lyophilization) and spray drying have been refined for optimal nutrient retention. Freeze-drying, in particular, works by sublimating ice directly from a frozen product under a vacuum, preserving the physical structure and chemical composition of delicate materials like fruits, vegetables, and even probiotics. This meticulous process ensures that volatile compounds and phytonutrients remain largely intact, yielding lightweight, shelf-stable ingredients that reconstitute beautifully and deliver potent nutritional value. These advancements are crucial for creating high-quality instant meals, nutritional supplements, and functional food additives.

The pursuit of quality extends beyond mere preservation to the active enhancement of food textures and flavors. Here, enzyme technology plays a pivotal role. Food scientists are now employing specific enzymes as precise tools to modify starches, proteins, and fats, achieving desired textures that were previously only possible with high levels of additives, sugar, or fat. For instance, transglutaminase, known as ‘meat glue,’ can restructure protein fragments into cohesive, whole-muscle-like products, reducing waste and improving yield. Similarly, specialized amylases can create pleasing mouthfeels in reduced-sugar products, ensuring that health-oriented offerings do not sacrifice the sensory pleasure that consumers expect, thereby bridging the gap between health and indulgence.

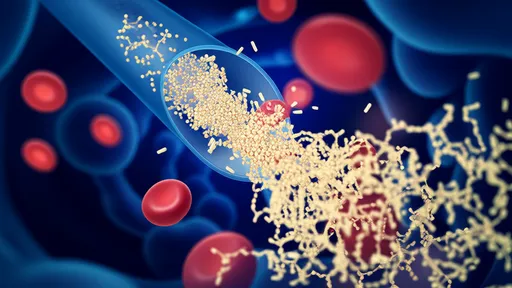

Perhaps the most personalized aspect of this technological wave is the development of nutrient delivery and encapsulation systems. A significant challenge in fortifying foods has been the protection of added nutrients—such as vitamins, omega-3 fatty acids, or minerals—from degradation during processing and storage, and also from altering the taste of the final product. Microencapsulation technology provides an elegant solution by enveloping these sensitive compounds in a protective matrix, often a biopolymer. This microscopic shield safeguards the nutrient until it is consumed and released in the digestive system, ensuring its bioavailability. This technology is revolutionizing functional foods, enabling the creation of staples like bread, milk, and juices that are powerfully fortified without any off-flavors or losses in potency.

Underpinning all these technological advancements is the critical and growing role of sophisticated data analytics and artificial intelligence. Modern food processing is no longer a series of isolated steps but a highly integrated, data-driven operation. AI algorithms can now optimize entire production lines in real-time, adjusting parameters like pressure, temperature, and flow rates to maximize nutrient retention for each specific batch of raw material, which can vary in its initial quality. Machine learning models predict how different processing conditions will affect the final product's vitamin content, texture, and color, allowing for unprecedented precision and consistency. This shift from a reactive to a predictive and adaptive model ensures that the promise of nutrition and quality is delivered in every single package, setting a new gold standard for the industry.

As we look toward the future, the trajectory of food processing innovation is clear. The focus will continue to sharpen on synergistic technologies that work in concert to protect and enhance our food. The ultimate goal is no longer just to feed the world but to nourish it, creating a food supply that is sustainable, safe, and inherently health-promoting. This requires a continued collaboration between food scientists, nutritionists, and engineers to push the boundaries of what is possible. The journey from viewing processing as a necessary compromise to recognizing it as a powerful tool for enhancing well-being is well underway, promising a future where the food on our plates is both a delight to the senses and a boon to our health.

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025

By /Aug 25, 2025